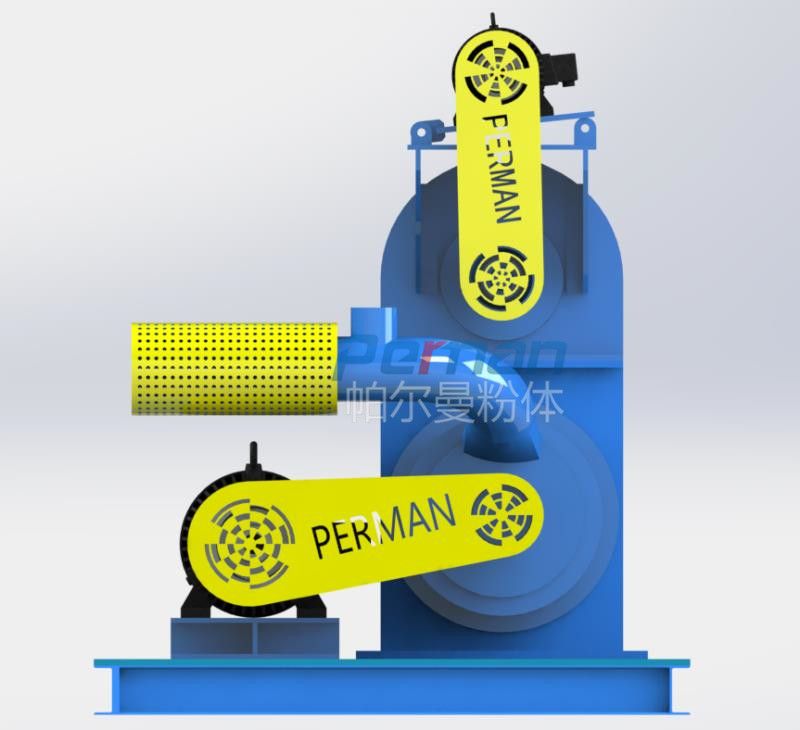

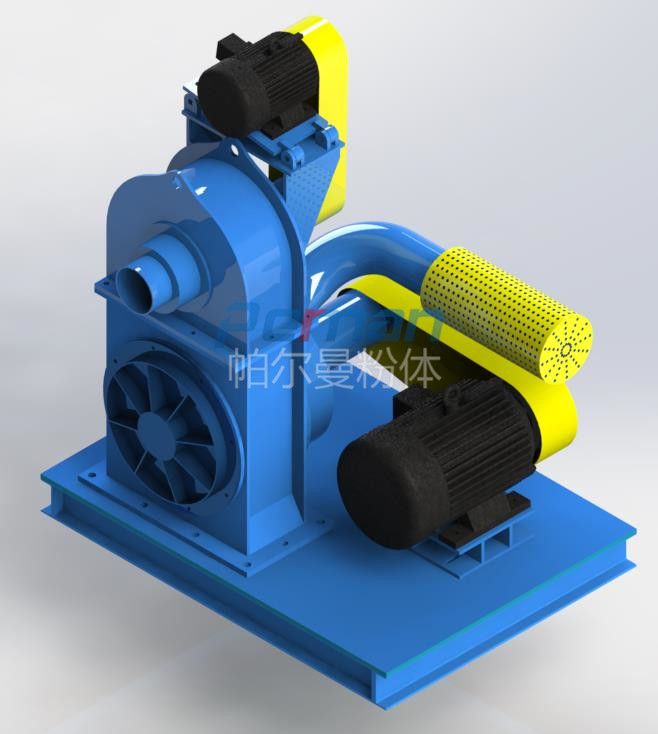

CAM-Y mechanical grinder

Product Introduction

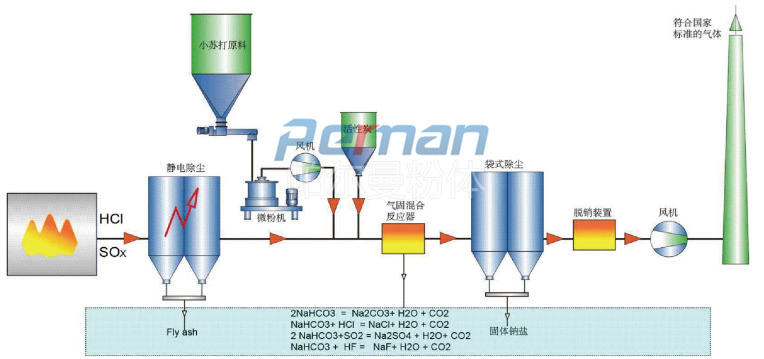

A two-stage impact ultra-fine grinding machine, including a first stage grinding machine, with a grinding channel installed on the upper part of the grinding machine, a classifier installed on the upper part of the grinding channel, connected by a flange plate, a fan for sucking the grinding material into the classifier, and a grading channel connected to the grinding channel at the lower part of the classifier. A secondary grinder with a lining plate added at the bottom and a grinding disc added inside. An independent doorway can be set up on one side for easy inspection. Place the secondary grinder under the classifier, and the materials that have been ground in the first stage will enter the secondary grinder with the airflow. After being impacted by the secondary grinding hammer, the materials will enter the classifier for sorting. The materials with qualified fineness will pass through the grading wheel and enter the collection system. Those that do not meet the requirements will return to the secondary grinding area for further grinding. To prevent the temperature increase of the cavity after secondary grinding, water circulation can be added to the outer wall of the cavity without damaging the material properties. After adding a secondary grinder, the production capacity and fineness of different materials can be increased by 30-60% compared to traditional mills, greatly reducing energy consumption. By repeating this process, the material is crushed more finely without any storage issues, thus improving the utilization rate of the material.

Product advantages

The two-stage impact ultra-fine grinding machine is a new type of ultra-fine grinding machine developed by Weifang Parman Powder Equipment Co., Ltd. on the basis of traditional grinding machines. The materials in the traditional grinding machine are quantitatively fed into the grinding machine, and collide with the gear ring through high-speed rotating grinding blocks. After grinding, they enter the grading area with the airflow. Some materials cannot return to the grinding area for secondary grinding, while others cannot obtain finer particle sizes even if they return to the grinding area due to limited primary grinding force. Some require regular slag discharge because they cannot be ground. After traditional grinding machines crush and classify materials, coarse materials cannot be returned to the grinding system for further secondary grinding. Even those that can return to the grinding area cannot obtain finer particle size requirements due to the weak grinding force in the grinding area. Only wet grinding or air flow crusher grinding can be considered, which has high energy consumption and extremely low grinding efficiency, greatly increasing production costs. Our company's two-stage impact ultra-fine grinding machine, with the addition of a two-stage grinding machine, can increase production capacity and fineness by 30-60% compared to traditional mills for different materials, greatly reducing energy consumption. By repeating this process, the material is crushed more finely without any storage issues, thus improving the utilization rate of the material.