Ton bag packaging machine

1. Structural Principle

The ton bag packaging machine adopts star-shaped unloader, spiral, arc door, vibrating feeder and other feeding structures. The control method is stepless frequency conversion speed control or multi-stroke cylinder control, combined with precision control valve to complete automatic packaging. After bagging, the packaging machine automatically completes the weighing, bag loosening, unhooking, and other work processes. The transportation can be manual, cylinder, or conveyor transportation.

This packaging machine is an economical packaging machine with a simple structure and a small footprint. It is suitable for quantitative packaging of bulk materials with good fluidity such as granular materials and powder materials.

2. Technical characteristics

1. Adopt star-shaped unloader unloading structure, frequency converter stepless speed control method, and cooperate with precision control valve to complete automatic quantitative packaging.

2. The packaging machine control system adopts PLC program control and has automatic and manual switching functions. Automatic is used during normal operation, and manual mode is used for debugging, maintenance and emergency treatment. It is simple to operate and easy to maintain.

3. The weighing instrument is a Toledo high-sensitivity digital display instrument with weight accumulation display, counting display, shift accumulation, automatic zero calibration, automatic tareing, automatic elimination of minor interference, automatic gap correction, over-tolerance alarm, fault self-diagnosis, etc. Function: The instrument is equipped with a variety of communication interfaces to facilitate networking, real-time monitoring, remote control and system network management.

4. Both the electrical control cabinet and the gas control cabinet adopt dust-proof structure and are well sealed. The protection level is IP65, which can avoid additional failures caused by dust pollution. The packaging machine is equipped with a dust removal interface to avoid pollution of the surrounding working environment caused by packaging.

5. Optional touch screen Chinese human-machine operation interface can realize dynamic display, monitoring, statistics, fault output and other functions, and has a help menu, making the operation simple and easy to understand.

3. Technical support

1. Provide technical support such as technical consultation, on-site inspection, scheme design, equipment supporting personnel training, etc.

2. Non-standard design can be carried out according to the actual needs of users and sites, product characteristics, process requirements, etc.

3. Optional devices

Configuration system, vacuum system, bag expansion system, anti-corrosion and explosion-proof, dust removal system, bag dust removal, cyclone dust removal, vibration device, conveying device, packaging device, hot melt sealing, interlocking control and remote monitoring and management of weighing data

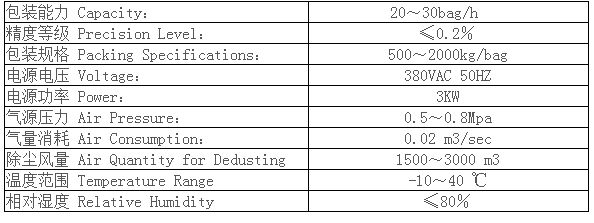

4. Technical parameters