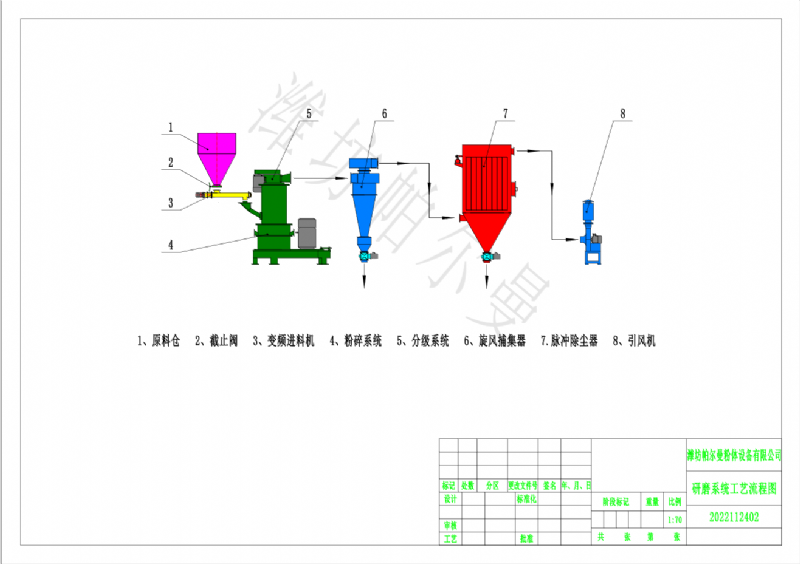

CAM-Z ultra-fine mechanical crusher

CAM-Z ultra-fine mechanical crusher

CAM-Z ultra-fine mechanical crusher is a multi-purpose powder equipment independently developed by our company. It has significant technical performance advantages such as low energy consumption, high fineness, low wear, and full functionality, and has become an equipment solution for many industries. Widely used in industries such as lithium-ion negative electrode materials (petroleum coke, needle coke), non-metallic mining, chemical industry, building materials, food, medicine, feed, new materials, environmental protection, and various dry powder materials for ultrafine grinding, dispersion, and particle shaping.

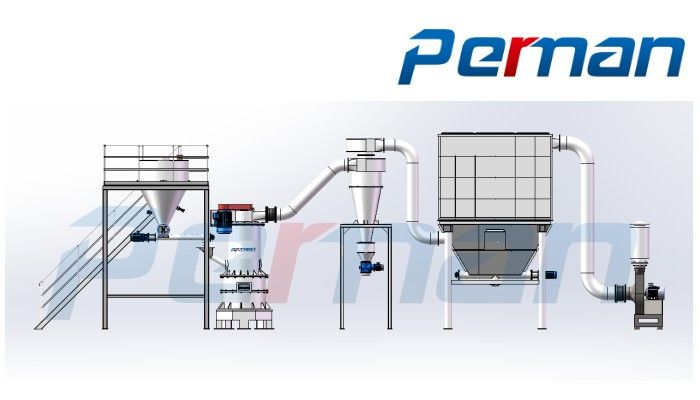

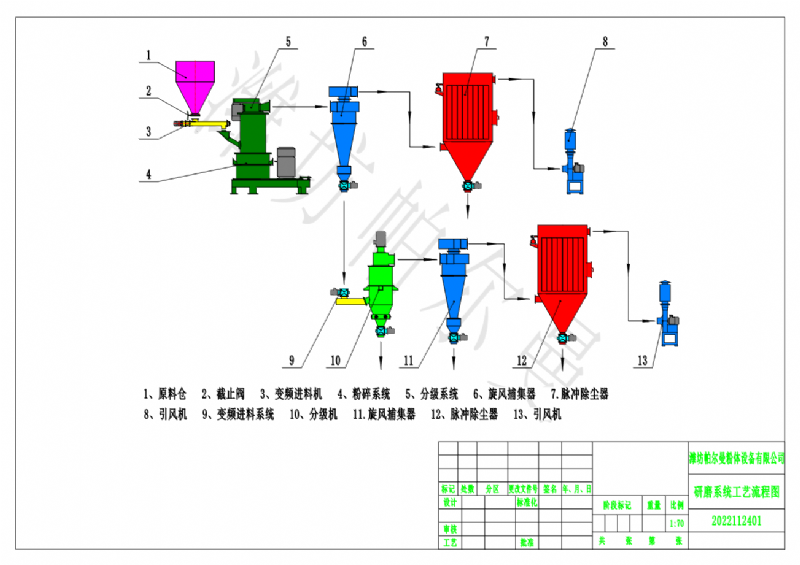

Process flow diagram

Technical advantages

(1) Low energy consumption: Combining various crushing methods such as centrifugal crushing, impact crushing, and extrusion crushing, it can save up to 40-50% energy compared to other types of mechanical crushers.

(2) High fineness: Equipped with a self splitting high concentration phase classification system, the crushing particle size can be adjusted between D50=5-15um.

(3) Low wear: The crushing part is made of composite wear-resistant new materials, the hammer head of the crusher is made of tungsten carbide wear-resistant materials, and the inner lining is made of chromium molybdenum alloy, which has a long service life.

(4) The host bearing adopts Japanese NSK, with oil circulation lubrication and water cooling, which extends the service life of bearings by 2-3 times compared to grease lubrication.

(5) The crusher host adopts two cooling methods, water cooling and air cooling, to ensure that the temperature of the equipment does not rise during long-term operation.

(6) The system has complete control measures and is equipped with overcurrent protection, as well as feedback control for feeding, grading, main engine, oil temperature, water temperature, and oil pressure.

technical parameter