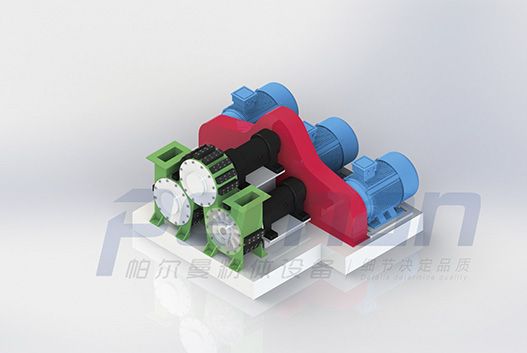

SQH three-roller shaping and spheroidizing machine

The SQH shaping and spheroidizing machine is a powder shaping machine model that Perlman has developed in depth for the deep processing technology of negative electrode material powder for the Chinese market. It is a mechanical and airflow mill. It is a multifunctional machine that integrates shaping, dispersing and powder crushing functions. The shaping function can be flexibly matched with various types of mills and greatly improve the performance of powder products. It can be widely used in the field of negative electrode material powder shaping.

SQH three-roller shaping and spheroidizing machine

Widely used in graphite: shaping and grading of flake, needle and fiber materials. It can meet the shaping requirements of negative electrode materials.

Technical advantages

1. It can achieve narrow and concentrated product particle size distribution curves and high product particle shape consistency.

2. To meet customer demands for products of various specifications, the granularity can be adjusted (product granularity D50=5~18um can be adjusted arbitrarily) with stable product quality and large output.

3. The entire production line adopts a fully sealed negative pressure system, which is environmentally friendly and high-performance, with no dust or large particle pollution.

4. PLC fully automatic intelligent control system, remote centralized control, one-button operation, and intelligent control technology realize high-performance and stable production. Brand new host transmission structure design, high output, low energy consumption and easy maintenance.

5. The main wear-resistant parts are made of high-quality wear-resistant alloy steel materials, which effectively improves the service life of the wear-resistant parts.

6. The entire production line has a compact structure, a small footprint, and low infrastructure costs.

7. Continuous and intermittent production can be achieved.

8. According to actual needs, you can choose continuous production or intermittent production technology. The two processes are slightly different. There is no need to stop the machine for feeding and discharging, and it is easy to operate.

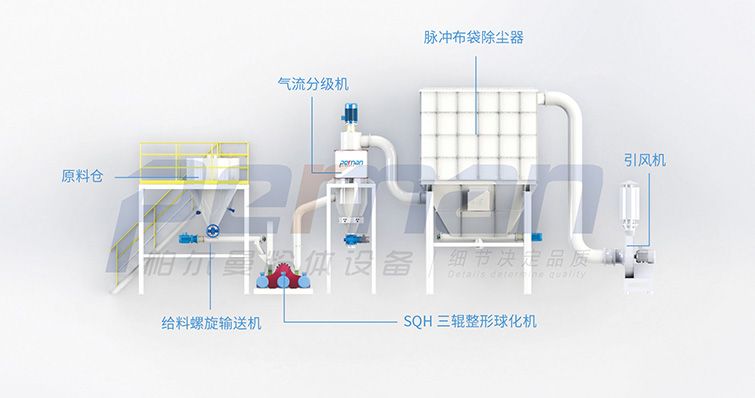

Process flow